CEW uses Guidewheel to support an aligned, transparent culture: “Each teammate understands how their work drives the success of the organization.”

Read MoreIn addition to recently released new Guidewheel features, such as new ways to easily subtract planned downtime, advanced filters and deep linking, and new AI-powered Tag Assist feature, check out our Tip of the Month!

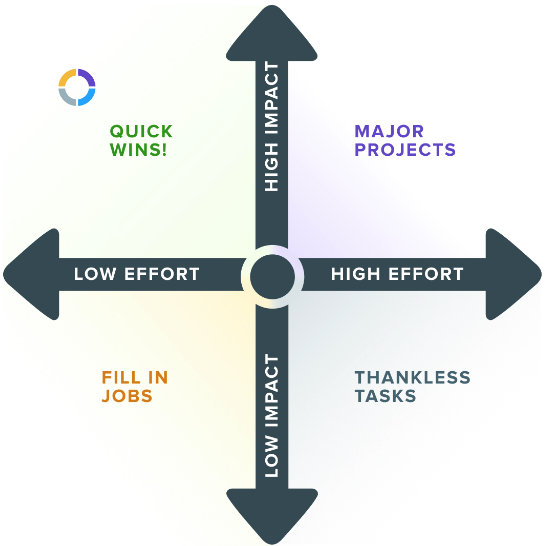

Read MoreShowing fast value is key to start the positive flywheel and drive momentum, excitement, and even more results… This builds the foundation to then take additional steps that can bring high additional value but also require more work.

Read MoreThe August issue of Eco-Plastics in Packaging contains an article on Guidewheel, “The Missing Link.” With increasing pressure around Sustainability, the article details how customers are using Guidewheel to drive both operational and energy efficiency.

Read MoreWe’ve released a comprehensive new Guide for leaders considering the best strategy to reduce risk and make the most of opportunities in the quickly-changing space of emissions reporting and management.

Read MoreIn this post, we compile background and advice from dozens of experts and manufacturers on the increasing movement to accurately track Scope 3 emissions from manufacturers within the supply chain.

Read More“Guidewheel allows us to track energy consumption at every one of our plants and direct production to the most energy-efficient manufacturing lines.” said Paul Kayser, CEO at Pretium.

Read MoreControlling costs doesn't have to mean cutting corners—it can be about finding smarter ways to operate. Here, we share guidelines to consider for a systematic approach.

Read MoreIn this post, we outline a few expected impacts of rising interest rates on manufacturing as well as some ways teams can stay resilient.

Read MoreThis post highlights how Pretium Packaging is simultaneously optimizing production and lowering energy consumption across their 25+ locations.

Read MoreThis recent panel covered multiple perspectives on how Industry 4.0 can impact EBITDA growth, enterprise value, and deal execution in today’s market.

Read MoreControl Engineering Magazine article on how using technologies like Guidewheel to improve changeovers can drive fast impact to the bottom line.

Read MoreGuidewheel empowers teams to reach peak performance by tackling the three major buckets that make up Overall Equipment Effectiveness (OEE), a gold standard measure of a factory’s productivity.

Read MoreWe’re thrilled to share that Guidewheel has closed an additional $9M in funding towards our mission of empowering all the world's factories to reach sustainable peak performance.

Read MoreIn this post we share tips and tricks on how to set up Guidewheel with ease, compiled from our customer support and implementation teams as well as from other customers.

Read MoreThe Manufacturing Executive podcast hosted Guidewheel this week for a discussion on aligning sustainability and profitability in manufacturing.

Read MoreEarly this year, Eddie and his team began focusing on using Guidewheel to track equipment idle time. Here we detail their goals, approach, and achievements.

Read MoreWe typically allocate a few days for install, although teams can get Guidewheel installed in as little as a few hours. The Guidewheel team is here throughout to support with any questions, and prepared to move as quickly as you are!

Read MoreQualityDigest showcased a piece describing how Guidewheel and FactoryOps are unlocking new approaches to Industry 4.0.

Read MoreThis week IndustryWeek published a detailed story describing how Penn Color has used Guidewheel to increase asset utilization by one-third. The full IndustryWeek story by Dennis Scimeca is linked here.

Read More